heavy duty bag making machine

Latest articles

Another benefit of stitching automatic machines is their versatility

heavy duty bag making machine...

heavy duty bag making machine 【heavy duty bag making machine】

Read Moreheavy duty bag making machine

...

heavy duty bag making machine 【heavy duty bag making machine】

Read More

...

heavy duty bag making machine 【heavy duty bag making machine】

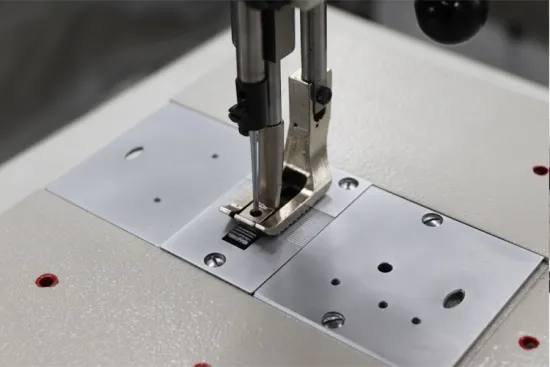

Read MoreThe machine is also equipped with a powerful motor that ensures smooth and precise stitching. Whether you are sewing straight lines or intricate patterns, the Cub Leather Sewing Machine can handle it all. Its adjustable speed settings allow you to control the stitching speed according to your project requirements

the cub leather sewing machine.

heavy duty bag making machine

...

heavy duty bag making machine 【heavy duty bag making machine】

Read MoreOverall, our special sewing machine has become an indispensable tool in our workshop. Its advanced technology, precision stitching capabilities, and user-friendly design have made it a favorite among our team of designers and creators. Whether we are working on a simple hem or a complex couture garment, this machine is always up to the task, delivering professional results with every stitch.

heavy duty bag making machine...

heavy duty bag making machine 【heavy duty bag making machine】

Read MoreDespite their advanced capabilities, heavy-duty sewing machines are designed to be user-friendly. Many manufacturers have made strides in making these machines accessible to both amateurs and seasoned sewists. With straightforward controls and clear instructional manuals, even those new to sewing can quickly learn to navigate their functions. Moreover, these machines typically have reliable performance, reducing the number of headaches that can come with sewing irregularities, such as thread jams or fabric bunching.

heavy duty bag making machine

...

heavy duty bag making machine 【heavy duty bag making machine】

Read MoreVersatility in Sewing Applications

heavy duty bag making machine

...

heavy duty bag making machine 【heavy duty bag making machine】

Read MoreAs industries continue to seek efficient and reliable packaging solutions, the significance of jumbo bag lock stitch technology will undoubtedly grow. By providing enhanced durability, secure sealing, and protection against contamination, lock stitching not only simplifies the handling of bulk materials but also bolsters the overall safety of the supply chain. For manufacturers and logistics providers aiming to optimize their operations, investing in jumbo bags with lock stitch technology is a strategic decision that promises to yield substantial benefits. As we move forward, this innovative stitching method will play an integral role in the evolution of industrial packaging solutions.

heavy duty bag making machine

...

heavy duty bag making machine 【heavy duty bag making machine】

Read MoreOne of the key features of hi-speed lockstitch machines is their ability to sew at incredibly fast speeds. These machines can stitch up to 5,000 stitches per minute, making them perfect for large-scale sewing projects or for quickly mending clothing. Their high stitching speed also ensures that seams are straight and even, giving garments a polished and professional finish.

heavy duty bag making machine...

heavy duty bag making machine 【heavy duty bag making machine】

Read More- Cost Efficiency The automation and speed of these machines reduce labor costs and production time, allowing businesses to operate more efficiently and economically.

heavy duty bag making machine

...

heavy duty bag making machine 【heavy duty bag making machine】

Read MorePopular articles

Heavy-Duty Sewing Machines: Maintenance routines for these machines are more frequent than industrial ones but less intensive. Regular cleaning, occasional oiling, and timely servicing should suffice.

Zig Zag Industrial Sewing Machine for Sale A Comprehensive Guide

Enhanced Creativity and Versatility

Furthermore, the design of these machines often includes specialized features that cater to the specific needs of auto upholstery. For instance, they may have extra-wide throat spaces to accommodate bulky materials, as well as walking feet mechanisms that ensure even feeding of multiple fabric layers. This is crucial when dealing with materials that can easily shift or bunch up during sewing. Additionally, many industrial sewing machines come with adjustable stitch lengths and widths, allowing upholsterers to customize their stitching for different applications.

Another benefit is the ease of adjustment. The single needle lock stitch can be easily modified in terms of stitch length and tension, allowing sewers to experiment and achieve the desired look and functionality. This adaptability is valuable, especially when working with different fabrics and project requirements.

Links

- Each supplier has its unique strengths and offerings, making it crucial for customers to evaluate their needs and choose a supplier that aligns with their specific requirements. Butyl rubber tape, with its robust properties and diverse applications, continues to be an indispensable material in various industries, and these suppliers play a vital role in meeting the global demand.

The Importance of Fireproof Gasket Tape in Safety and Efficiency

3M Electrical Rubber Tapes: The Ultimate Guide to Top Performance & Applications

rubber car door seal strip. Made from high-quality rubber materials, these seals can withstand extreme temperatures, UV rays, and other environmental factors without losing their shape or flexibility. As a result, they can last for many years before needing to be replaced.

rubber car door seal strip. Made from high-quality rubber materials, these seals can withstand extreme temperatures, UV rays, and other environmental factors without losing their shape or flexibility. As a result, they can last for many years before needing to be replaced. electrical pvc tape manufacturers. Marking The tapes can be used to mark wires, cables, and other components with information such as voltage levels, circuit numbers, and installation instructions.

electrical pvc tape manufacturers. Marking The tapes can be used to mark wires, cables, and other components with information such as voltage levels, circuit numbers, and installation instructions.Selecting the right tape for motor connections

Your control box design should factor in numerous thermal aspects including the type of power supply and heat dissipation of your chosen materials. Ensure your box has elaborate airflow management features to maintain a safe operating temperature.

Wall-Mounted Control Boxes

What Temp does Electrical Tape Melt?

A control box is an advanced electrical component that allows you to keep an eye on your connected devices and manage their operations. This physical interface comes with numerous high-end components with distinct roles key amongst them being monitoring and control.

Polyethylene Rubber Tape is composed of a polyethylene backing material with a rubber-based adhesive. Polyethylene is a thermoplastic polymer known for its excellent resistance to moisture, chemicals, and abrasion. The rubber adhesive provides strong adhesion to different surfaces.

Butyl rubber waterproofing is also highly versatile and can be used in a variety of applications. In construction projects, it is commonly used to seal joints, seams, and penetrations in buildings, ensuring that water cannot seep through and cause damage. In industrial settings, butyl rubber waterproofing can be applied to storage tanks, pipelines, and other structures to prevent corrosion and deterioration. In residential buildings, butyl rubber waterproofing can be used to protect basements, roofs, and balconies from water infiltration, extending the lifespan of the building and reducing maintenance costs.